Product safety testing and certification are crucial pillars of a successful brand strategy. Ensuring your products meet regulatory, quality, and safety demands not only protects consumers but also builds brand trust. Navigating the certification landscape can seem overwhelming—here’s how your brand can master the process, stay compliant, and thrive in competitive markets.

Understanding Product Compliance: Why Safety Testing Matters

Product compliance is more than a legal obligation—it’s a demonstration of your brand’s commitment to consumer well-being. Safety testing verifies that a product meets both national and international standards. In 2025, consumers are more informed than ever, using safety certifications to gauge quality. Failing to comply can result in seized shipments, costly recalls, or irreparable reputation damage.

Today’s regulatory environments, from the U.S. Consumer Product Safety Commission (CPSC) to the European CE marking, continually evolve. Proactive brands regularly update compliance strategies to identify and mitigate potential risks early in the product life cycle. Beyond legal risks, high-profile recalls highlight why robust testing is also a competitive differentiator.

Types of Products Requiring Certification and Common Standards

Almost every product category requires some form of safety validation, but standards vary by industry and region. Here’s a look at some categories and applicable certifications:

- Children’s products: Must undergo testing for toxins, sharp points, and choking hazards. ASTM F963 and EN71 are prominent standards.

- Electronics: Require electromagnetic compatibility (EMC), electrical safety, and often RoHS (Restriction of Hazardous Substances) compliance—think UL or CE marks.

- Textiles and apparel: Oeko-Tex and REACH certifications screen for banned substances and allergy risks.

- Cosmetics: Must comply with FDA or EU Cosmetic Regulation. Microbial and toxicological safety are checked.

- Food-contact materials: Materials must pass migration and toxicity tests under FDA or EU 10/2011 standards.

Brands must research the latest requirements applicable to each target market, as national differences are increasingly scrutinized in global distribution.

The Product Safety Testing Process Explained

Product safety testing typically follows a repeatable procedure—from design to post-market surveillance:

- Hazard identification: Assess your product design and materials for risks—chemical, mechanical, or electrical.

- Standard selection: Determine which local and international standards apply. A compliance consultant can minimize oversights.

- Sample preparation: Select production samples that represent your typical manufacturing output for laboratory analysis.

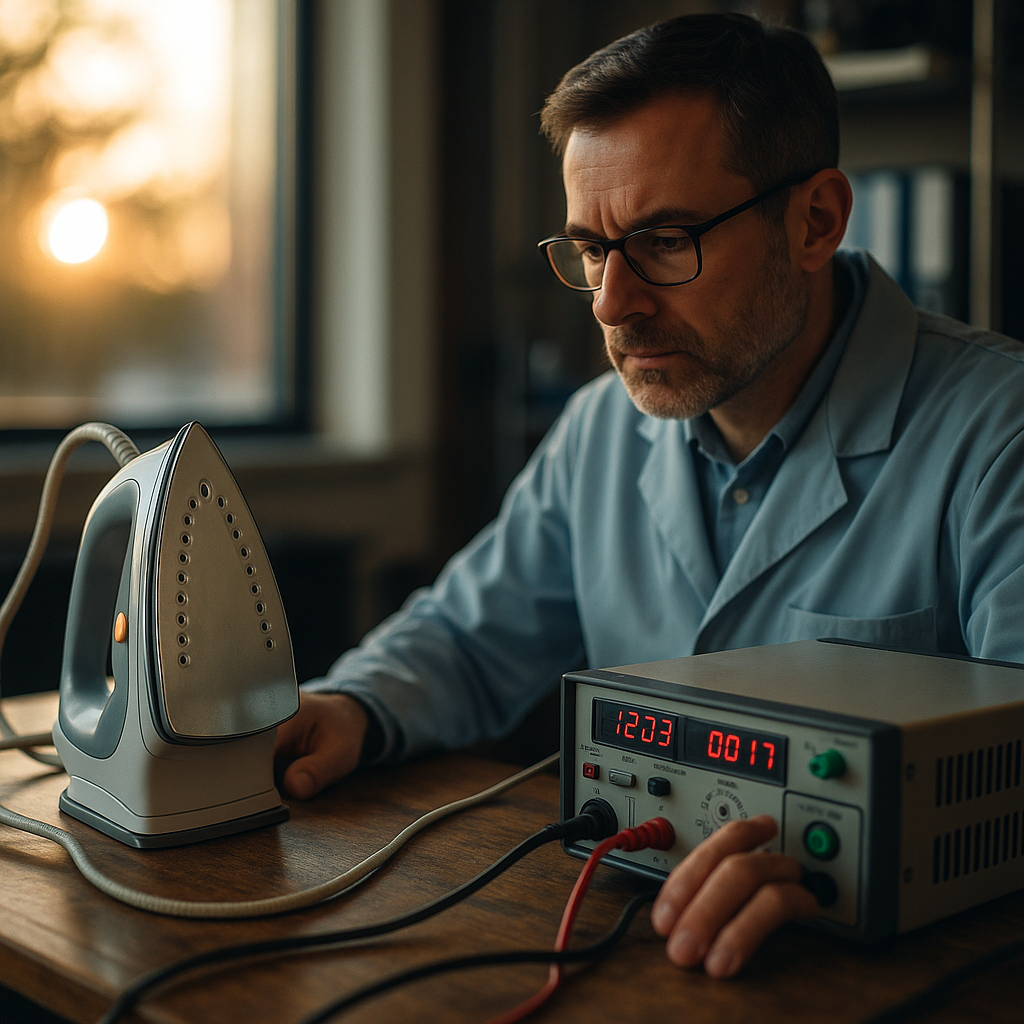

- Laboratory testing: Certified laboratories perform relevant tests—flammability, drop, chemical leach, or circuitry analysis.

- Reporting and evaluation: Receive a test report outlining pass/fail results and any corrective actions needed.

- Documentation: Prepare technical files and Declarations of Conformity for regulatory bodies and retailers.

Transparency is essential. In 2025, many retailers require digital documentation before listing new products, underpinning the need for rigorous and traceable records.

The Certification Journey: Navigating Global Markets

Certification unlocks market access, enabling your brand to distribute across jurisdictions—each with distinct requirements. The regulatory environment in 2025 places greater importance on harmonized standards, but there are still key differences:

- United States: CPSC, FCC, and FDA certifications are mandatory for many product types. Assembly and labeling must follow precise rules.

- European Union: CE marking covers safety, health, and environmental protection. The EU also emphasizes eco-design and sustainability.

- Asia-Pacific: China Compulsory Certification (CCC) and Japan’s PSE mark address regional concerns, including new rules for IoT devices.

Brands launching in multiple markets must harmonize testing—working with internationally accredited laboratories and recognizing which certificates are mutually accepted. Early engagement with notified bodies or third-party certification agencies prevents costly launch delays.

Choosing Reliable Partners for Product Safety Testing and Certification

Selecting a trustworthy laboratory or certification body maximizes the credibility of your product claims. Look for partners that demonstrate:

- Accreditation: ISO/IEC 17025 or similar recognition signals global competence in testing and calibration.

- Industry expertise: Experience with your product type and target markets enhances the accuracy and speed of compliance.

- Transparency: Detailed timelines, communication, and digital tracking tools ensure visible progress at every step.

- Value-added support: Assistance with risk assessment, technical documentation, and post-market obligations strengthens your compliance stance.

In 2025, digital platforms simplify test scheduling, real-time status updates, and records management. Brand owners should prioritize partners offering these capabilities to streamline their compliance processes and foster ongoing market readiness.

Integrating Safety Testing into Your Brand’s Workflow

Integrating safety testing into your development cycle reduces surprises and accelerates time-to-market. Best practices include:

- Early planning: Budget for safety testing and mark critical compliance checkpoints in your project timeline.

- Cross-functional collaboration: Engage R&D, quality, legal, and sourcing teams to align on standards and processes.

- Continuous improvement: Review incidents, market feedback, and evolving regulations to adapt your protocols.

- Training and awareness: Educate staff on compliance updates and best practices using regular workshops and e-learning.

Leading brands treat compliance as more than a checkbox—it’s a driver of product innovation and consumer trust. Embedding safety as a core value pays dividends in long-term reputation and operational resilience.

Product Safety Testing and Certification for Brands: FAQs

- Is safety testing required for every product?

Most consumer products require safety testing, especially those intended for children, electronics, or skin contact. Requirements depend on category and destination market. - How long does product certification take?

Timelines vary by product complexity and the number of required tests, ranging from a few weeks to several months. Early planning helps avoid delays. - What happens if my product fails a test?

Failed results mean revisiting design or materials. After corrective actions, retesting is mandatory until standards are met. - Do small brands need certification, too?

Yes, size doesn’t exempt brands from compliance. Certification is essential to ensure market access and consumer safety. - Can certification be used in marketing?

Absolutely. Certifications signal quality and diligence, often influencing purchase decisions and retailer acceptance.

Smart brands in 2025 make product safety testing and certification a cornerstone of quality and trust. By proactively addressing compliance, you not only meet legal obligations but also gain a vital competitive edge—ensuring your products reach, delight, and protect customers around the world.